Step 1: How to Plan Your Carpet Cleaning Maintenance Program?

You have just installed new carpets for your home or office, and you have no idea how to clean and maintain it.

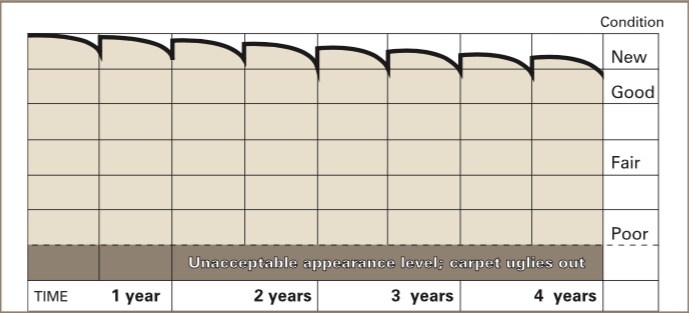

Time is of the essence, it will be too late if you wait until your carpet is overly soiled thus risking your carpet uglying out.

Therefore, this carpet cleaning and maintenance guide is intended to share comprehensive information on the knowing and planning process.

Guided by this carpet cleaning guide, maintenance can be concentrated in the high traffic areas and any areas that rapidly re-soil, with periodic all-over cleaning to prolong the useful life of your carpets.

Appearance maintenance.

There are two key factors that will affect the appearance of your carpet after installation:

a) Flattening, matting or shading of the carpet fibre.

b) Soiling, change in colour and general staining of the carpet.

Maintaining the appearance of your carpet requires that:

a) Cleaning products selected are appropriate for their intended area of use.

b) Regular cleaning is carried out to prevent soiling, which may cause carpet fibres to mat and bind together.

Soil prevention and maintenance routines.

Most soil is transferred to the carpet from foot traffic.

The use of an effective dirt barrier matting will greatly reduce the rate of soiling.

Dirt barrier matting should be installed for the first three metres (minimum) of all external entrances, goods lifts, loading and off-loading docks and adjoining hard areas.

It is very important that the dirt barrier matting is maintained and serviced on a daily basis.

Once the dirt barrier matting is full of soil, it ceases to be effective.

All concrete areas adjoining your carpeted area should be sealed with an appropriate permanent resinous sealer which will prevent particles of sand, gravel or cement being tracked onto the carpet.

An epoxy or urethane sealer is recommended.

These sealed areas should be thoroughly cleaned daily, removing any visible soil and stains by mopping with a neutral pH level detergent.

The use of an anti-soiling spray directly on your carpet is not recommended.

First aid for carpet.

Prompt action using a Spot Cleaning Kit assists in easy, complete removal of most spots and stains.

The following initial procedures should be applied to treat all spillages and stains on your carpet.

-

- If the spill is liquid, blot up as much of the spill as possible with a clean white cloth.

-

- If the spill is semi-solid, scrape with a spoon or spatula and then blot with a damp sponge.

-

- Work from the edge of the spot towards the centre.

-

- Never rub a wet spill; this will only spread the problem.

If the spill proves difficult to remove remember that the stained or damaged tile can be replaced with a tile from your shelf stock.

Water based spillages.

-

- After following the above procedure, promptly remove the remaining residue with a small amount of Dry Absorbent Compound and a hand brush.

-

- Sprinkle the Compound over the spot and use a hand brush to gently massage the Compound into the stain.

-

- Allow the area to dry (15-30 minutes) and then brush the Compound again.

-

- If the Compound seems to stick to the carpet, brush again, then vacuum.

-

- Repeat the application if necessary.

-

- Do not rub the brush aggressively on the spot.

For difficult to remove coffee, tea, juice or soft drink stains use a general purpose spot cleaner in the following manner:

-

- Pre – Test a small inconspicuous area for possible discolouration prior to use.

-

- Pre – Clean the area using a small amount of general purpose spot cleaner and rinse with water.

-

- Blot dry with an absorbent cloth or paper towel.

-

- Repeat the procedure if necessary.

Oil based spillages.

For the removal of oily stains such as paint, grease, tar, asphalt, etc., solvent based spotter is recommended.

Caution should always be taken when using any type of penetrating spotter.

-

- First check colourfastness.

-

- Test on the carpet in an inconspicuous area by applying the solution on to a white cloth and gently pressing onto the carpet.

-

- Check the cloth, if there is any evidence of dye transfer to the cloth, do not continue.

-

- Apply solvent based spotter sparingly to a clean white cloth, then apply the cloth to the spot. Again do not rub, it will only spread the problem.

-

- Wipe gently from the outer edge towards the centre of the spot.

-

- Repeat procedure until the spot has been removed.

-

- Place a clean white towel or absorbent tissue over the treated area until dry.

-

- Follow with an application of Dry Absorbent Compound.

Gum removal.

To remove chewing gum, use the following steps:

-

- Apply solvent based spotter directly to the chewing gum.

-

- Leave for several minutes to allow the solvent spotter to soften chewing gum.

-

- Remove as much gum as possible using a paint scraper or a knife.

-

- Apply a small amount of solvent based spotter to a clean white cloth.

-

- Working from outside in, remove any residue of the chewing gum.

-

- Rinse well with clean water.

Daily removal of spots and spills.

Ensure that a Spot Cleaning Kit is available at all times to enable quick treatment of all spillages.

Any stain or spot not removed by an approved method, is to be noted in a daily log, together with details of the methods used in the attempted removal for future reference.

If unattended, these stains become difficult to remove and will attract more soil.

Step 2: Planning a Carpet Cleaning Maintenance Program.

Carpet can only perform if it is maintained properly.

Failure to do so will adversely affect the life and appearance of your carpet.

A maintenance program is a comprehensive plan which maps out the future maintenance schedules for the product.

It provides a system which will maintain the appearance retention for the life of the investment.

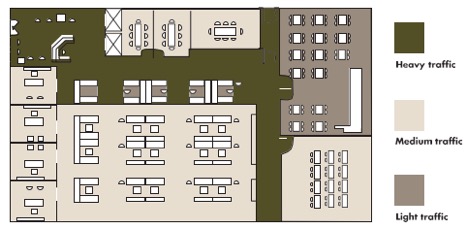

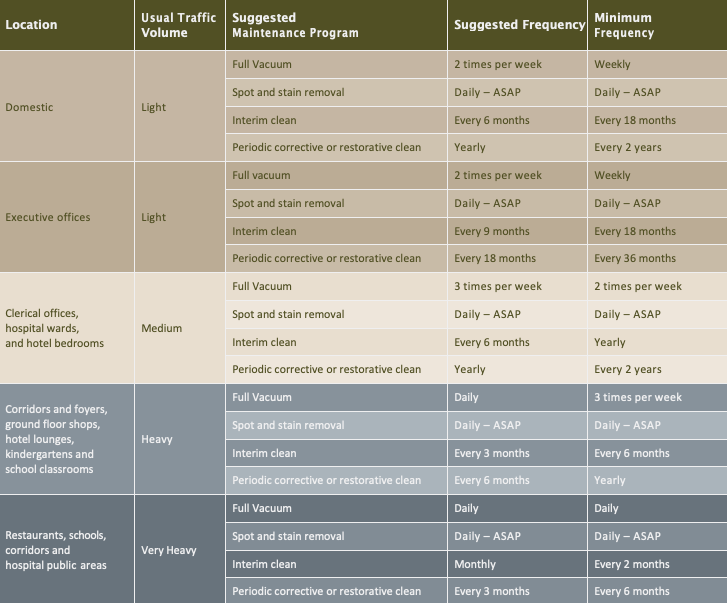

The maintenance program is developed around the traffic volume and soiling rates of the different areas throughout the installation.

Frequencies need to be established in consultation with a qualified local carpet cleaner.

Improper techniques and frequencies can risk voiding the end users warranty.

When developing a maintenance program each facility is different therefore all programs must be customised accordingly.

Daily maintenance.

Daily maintenance involves day to day vacuuming and carpet spotting utilising a Spot Cleaning Kit.

Heavy traffic areas may require more regular cleaning.

Vacuuming should involve recommended equipment, using overlapping passes of the area at a constant speed.

Interim maintenance.

Interim maintenance is carried out on a weekly, monthly basis or on demand.

It will usually involve an interim cleaning method as required.

The maintenance plan will stipulate which areas need to be cleaned.

Usually this would be the heavy and medium traffic areas of your carpet.

The mix of interim and periodic cleaning will vary with each maintenance program.

Periodic maintenance.

An integral part of your maintenance program should be a Periodic Clean, which encompasses the entire carpet.

It is important that on a quarterly, half yearly and/or an annual basis your whole carpet is cleaned utilising a Hot Water Injection and Extraction method.

This ensures that the appearance of your carpets are kept uniform.

Whenever in doubt, please feel free to contact your Singapore carpet cleaning specialist.

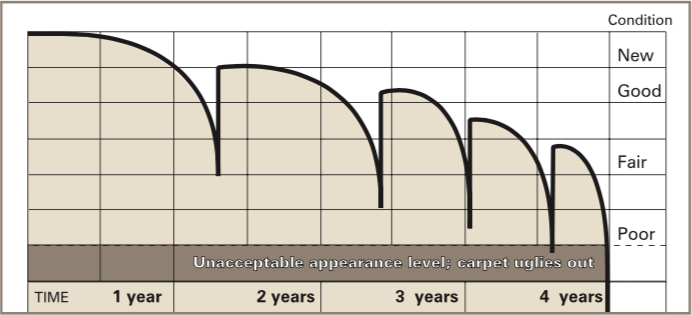

Diagram 1: Example of a graded traffic volume plan for a maintenance program.

Carpet appearance level: Planned program

Planned maintenance program:

1. Traffic areas and spots receive the most attention.

2. Appearance will be good everyday. Carpet life is extended.

Carpet appearance level: Unplanned

Unplanned – crisis cleaning:

1. Carpet is allowed to soil excessively before cleaning

2. Appearance is often dingy. It appears to ugly out before it wears out.

Step 3: Selecting your Carpet Cleaning Maintenance method.

To be able to implement the maintenance program access to the correct equipment is essential.

Carpet cleaning with incorrect, non-approved methods, equipment and chemicals may result in damage to the your carpet and invalidation of the warranties.

Vacuum equipment.

It is recommended that the following equipment be utilised when vacuuming your office carpets.

1. Commercial canister-type vacuum with power head containing a rotating cylindrical

2. Commercial top loading upright vacuum with twin motor and rotating cylindrical brush.

Both vacuums must have tools that can access edges and hidden areas.

Vaccum filteration systems must be capable of filtering 97.5% of dust to 0.5 microns.

Vacuum bags should be disposable.

Interim and periodic maintenance method.

The following carpet cleaning procedures recommended for use should be carried out by trained accredited operators.

Dry extraction (Low Moisture Absorbent Compound) (Interim).

Dry extraction involves massaging a low moisture absorbent compound into the carpet surface to remove soil and stains.

Residual compound is then vacuumed from the carpet pile.

Method:

-

- Thoroughly pile lift and vacuum carpet.

-

- Spread the Dry Absorbent Compound as per manufacturer’s instructions.

-

- Brush in the Compound as per manufacturer’s instructions.

-

- Vacuum the Compound residue from the carpet.

-

- Hot water extraction is recommended approximately once a year in conjunction with this system or as specified by your carpet cleaning maintenance plan.

Encapsulation / Crystalline Shampoo Application (Interim).

The encapsulation/crystalline shampoo method of maintenance is a low-moisture procedure similar in some respects to the dry extraction method.

Benefits include faster access to the area than with hot water extraction and reduced drying times.

Preparation should always include vacuuming and pile lifting before applying the Encapsulation/Crystalline Shampoo using an electric sprayer, a simple pump-up garden type sprayer.

The carpet pile is then gently brushed so the solution is applied to all the fibres whilst dislodging and dispersing any accumulated soil.

Time should be allowed for the solution to dry and form the encapsulating crystalline formations around the fibre which effectively trap any soils and other contaminants.

Drying time will vary according to several factors including humidity, air flow and ambient temperature, but it can be expected to be anything from 60 minutes.

Once it is dry the area can be vacuum cleaned and pile lifted.

Bonnet Cleaning.

Bonnet or spin cleaning involves a rotary floor machine with a cleaning pad soaked in solution.

As it moves over the carpet, the agitation causes dirt to be absorbed into the cleaning pad.

The cleaning solution used with bonnet machines uses optical brighteners such as bleach which polish the cut fibers of the carpet, making the carpet appear brighter and cleaner.

Unfortunately, though bonnet cleaners are able to remove some surface dirt, they also end up pushing a lot of dirt and cleaning solution further down into the carpet pile.

This residue can then become a magnet for even more dirt.

This type of carpet cleaning may void warranties; please check before engaging in this carpet cleaning method.

Hot water injection and extraction (Interim/Periodic).

Hot Water Injection and Extraction involves a pre-spraying chemicals into the carpet and then extracting it with clean hot water utilising approved equipment and methods.

For corrective or restorative cleaning, it is recommended that a trained and accredited Carpet Maintenance Technician perform this task.

As the carpets can be damp after Hot Water Extraction cleaning, always ensure that the mechanical air blowers bear the Singapore Safety Mark.

Method:

Pre-spray carpet with an approved Extraction Pre-Spray.

Operate the floor wand or self contained extractor by engaging the solution valve, applying clean hot water only.

Pull equipment towards the operator for 1m–1.5m before releasing the solution valve.

Cover the same area 2–3 times with the solution valve off to ensure as much moisture as possible is removed from the carpet.

Overlap approximately 50mm and proceed on next section of untreated carpet.

Place drying fans on wet areas during cleaning and allow the carpet to completely dry before reintroducing foot traffic.

Failure to do so will result in rapid resoiling and damage to the carpet fibre.

In cases of highly soiled areas the prespray detergent may require mechanical agitation with a cylindrical brush machine.

Chemicals.

It is essential to realise that carpets are chemically sensitive fabrics which could be damaged by non-recommended chemicals.

Use only approved chemicals for pre-spray or spotting on an “as required” basis.

Access to a Spot Cleaning Kit is recommended for day to day spot cleaning.

For spotting and pre-spray the pH should be between 4.5and 8.5.

Anti-static treatments, optical brighteners, carpet protection chemicals and overly aggressive solvent based cleaners are not recommended for Interface products.

Key points to remember.

Walk-Off Areas.

One of the most effective preventative maintenance steps is a dirt barrier matting area at entryways, exits and any areas adjacent to hard surfaces.

Dirt barrier matting areas should be vacuumed daily or as needed.

Vacuuming.

Must be done slowly and methodically with a commercial upright, dual motor vacuum with a cylindrical brush.

Pile-lifting.

Regular pile lifting with a motorised commercial pile lifter keeps the fibre standing upright and separated.

In addition to alleviating matting, this procedure will make the vacuuming more effective.

Soil is always easier to remove “dry” than wet.

Spotting.

Addressing spots immediately can lower the frequency at which overall cleaning is needed.

Low Moisture.

When general cleaning becomes necessary, use as little water as possible.

Traffic.

Carpet should be completely dry before reintroducing traffic.

Failure to do so will result in rapid re-soiling and damage to the carpet fibre.

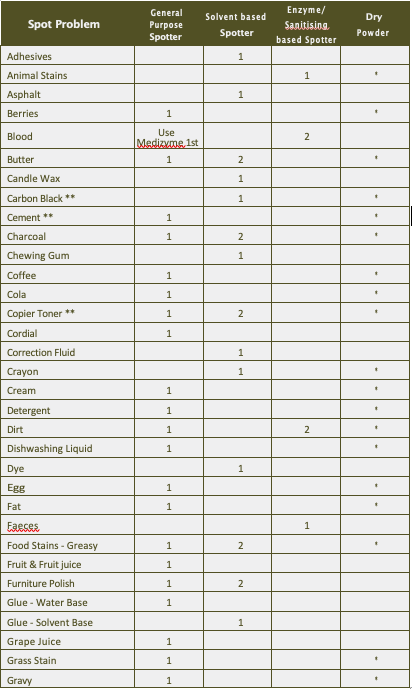

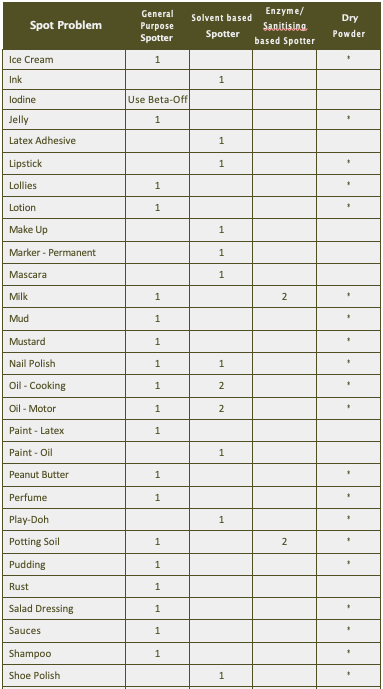

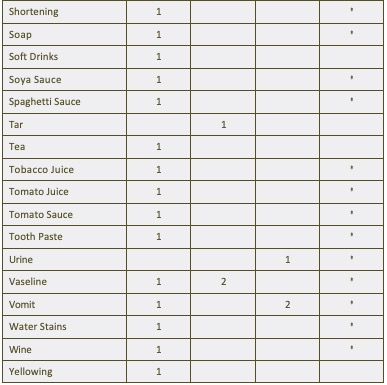

Spot Cleaning and Solution Guide.

For the following Spot Problems, please try solution 1 first, before trying solution 2.

If some staining remains, please try solution 3.

Dry Powder may be used as a quick, dry, low odour alternative.

** For these spot problems, vacuum first and then follow the solutions suggested.

Instructions for spot cleaners.

-

- Clean up all spills promptly before a spill becomes a permanent stain

-

- Remove excess soil or liquid from the carpet. For soil, gently scrape away surface spill with a spatula or knife, and for liquid spills dab area with an absorbent colourfast cloth.

-

- Where possible try to identify the type of stain; look, feel and smell.

-

- Always pre-test the spotter in asmall inconspicuous area before using. This is to determine if the product is going to have any adverse effects on the surface.

-

- Apply spotter with a clean white cloth and gently dab the stain working from the outside towards the centre.

-

- For deep stains apply spotter directly to the carpet. DO NOT over-wet the carpet.

-

- Rinse the area with water after the stain has been removed.

-

- Repeat steps for stubborn stains.

General Purpose Spot Cleaner.

-

- Remove loose dirt or lift off as much of the spilt material as possible. If a wet spill, blot the affected area with a clean colourfast cloth or absorbent towel. Blot from the outer edge of the stain towards the centre. Do not scrub.

-

- Spray affected area with spot cleaner. Wait a few moments and then gently rub with a clean, colourfast damp cloth. Rinse cloth and repeat until mark is removed from the carpet. (Do not over-wet the carpet.)

-

- Rinse well with clean water to remove detergent residue and allow to dry.

Solvent based Spot Cleaner.

-

- Apply undiluted directly to the stain (use sparingly and avoid product penetrating to carpet tile backing.)

-

- Using a small soft brush or cloth lightly scrub the spot starting from the outside and working towards the centre.

-

- Absorb as much solvent spotter as possible from the surface using an absorbent cloth.

-

- Rinse well with clean water to remove detergent residue and allow to dry.

Enzyme/Sanitising based Spot Cleaner.

-

- Remove as much excess soil as possible.

-

- Apply undiluted enzyme/sanitising based Spot cleaner directly to the soiled area using a trigger spray.

-

- Gently work enzyme/sanitising based spot cleaner into the carpet pile.

-

- Remove excess with blotting cloth.

-

- Rinse well with clean water to remove detergent residue and allow to dry.

NOTE:

For hot water extraction apply a hot water extraction prespray. This should be applied to the carpet with a pressure spray unit then rinsed from the carpet with a hot water extraction machine.

The hot water extraction machine should use clean hot water of room temperature or no more than 45°C and the tiles should be left with no more than 30 grams of residual moisture after cleaning.

For best results, use promptly after spot occurs.

If unsuccessful, contact a singapore carpet cleaning specialist.

Stubborn stains may require the services of a professional carpet cleaner.

Please make sure to use protective gear when encountering excess biological contamination and/or accumulation.

Avoid overuse or careless excess spray as irritation may occur.

Carpet Cleaning Maintenance Equipment Recommendations.

Using the right equipment is as important as using the right cleaning solutions and the best techniques.

The following guidelines provide the technical specifications for essential carpet maintenance equipment.

Vacuum (for twin motor uprights).

Power: 8 Amp

Filtration: Down to 0.3 microns or lower

Vacuum: 60” water-lift motor or better @ 90+ cfm

Brush: Toothed belt drive preferred Brush speed 2,500 – 5,000 Rpm Brush diameter 2H” x 3 1/2H”

Brush height: adjustment essential; self-adjusting design preferred

Working Width: 15” – 22”

Dust Bag Capacity: 300 – 400 cubic inches

Pile Lifting Equipments.

Power Requirements

Drive Motor: 1/2 Horsepower

Vacuum Motor: 1 1/2 – 1 3/4 Horsepower

Brush Width: Approximately 100mm; Spirals, total width 400mm – Vegetable Fill or Nylon Counter-Rotating

Brush Adjustment: Self Levelling

Hot Water Extraction Machines.

Power Requirements: 10 – 15 Amps 220 – 240 Volts Vacuum Motor 1500 Watt

Vacuum Type: 3 Stage by-pass

Vacuum Shoe: 300mm – 500mm

Water Lift: 2.5m – 3.5m At 100 CFM

Fluid Delivery: 2 Litres/Minute at 50 – 100 PSI

Solution Tanks: 15 Litres Upwards for both solution & Recovery Brush Motor 90 Watt 1/8 Horse Power

Brush Width: 250mm – 450mm with 4v-Shaped rows of Nylon Bristles

Extraction Compound Application Machines.

Power Requirements: 2 – 8 Amps 220/240 Volts Motor 200 Watt

2 Brush System: Counter-Rotating

Brush Width: 250mm – 500mm

Brush Speed: 400 Rpm

Crystalline Shampoo Systems Dry Extractor and Crystalline Applicator.

Power: 2 – 8 Amps

Width: 12” – 22”

Brushes: (2)10” – 20” Counter-Rotating

Brush Speed: 400 Rpm

Your carpet stores the most dirt and dust.

To enjoy optimal indoor air quality, proper and regular cleaning of your carpets is of paramount importance.

In order to keep our carpets happy and healthy, an effective carpet cleaning and maintenance program is vital for any home or office.

Until then, all the best, take care and see you soon!